Continuous improvement is the key to staying competitive and achieving long-term success in today’s dynamic business environment. One of the most effective tools in driving this improvement is CAPA (Corrective and Preventive Action). CAPA helps organizations not only address existing problems but also prevent future issues.

In this article, we will explore how CAPA drives powerful continuous improvement results and why it is essential for maintaining high-quality standards across industries.

What is CAPA?

To understand how CAPA drives powerful continuous improvement results, we must first define it. CAPA, or Corrective and preventive action ion, is a structured process that helps organizations identify the root causes of non-conformances, deviations, or failures. This process ensures that companies address issues and take steps to prevent them from happening again. Corrective and preventive action not only fixes problems but also creates a system that keeps them from recurring. It drives continuous improvement by making quality control processes stronger and more reliable.

The Corrective and preventive action process consists of two main phases: corrective and preventive actions. In the corrective action phase, companies focus on identifying and fixing current problems. They take immediate steps to correct issues and restore normal operations. The preventive action phase goes further by addressing the underlying causes to prevent future issues. This forward-thinking approach ensures that similar problems don’t arise again. By implementing both phases, it helps companies continuously improve their processes and overall performance.

Sign up for GMP Corrective and Preventive Actions (CAPA) Management Course

How Does CAPA Drive Powerful Results?

CAPA drives powerful continuous improvement results by enhancing several key areas of business operations.

Let’s break these down:

Improved Quality Control

When an issue arises, Corrective and preventive action ensures that it is properly documented, investigated, and corrected. This process enhances overall quality control by identifying areas for improvement and ensuring compliance with regulatory requirements.

Increased Efficiency

CAPA helps streamline processes by eliminating inefficiencies that may lead to quality issues. By addressing problems at the root, businesses can reduce downtime, improve workflow, and optimize resources.

Enhanced Compliance

For industries like pharmaceuticals, medical devices, and manufacturing, compliance is critical. Corrective and preventive action helps ensure that businesses meet regulatory requirements by documenting corrective and preventive actions, allowing organizations to stay audit-ready.

Stronger Customer Satisfaction

Customers expect consistent quality, and Corrective and preventive action plays a crucial role in meeting these expectations. By ensuring that products and services are free from defects and continuously improving, businesses can build stronger relationships with their customers.

Why is CAPA Critical for Continuous Improvement?

CAPA Focuses on Root Causes, Not Just Symptoms

CAPA is essential for continuous improvement because it digs deep into the root causes of problems, rather than just addressing their symptoms. By identifying why an issue occurred in the first place, it helps businesses avoid quick fixes that don’t last. This approach leads to more effective solutions that improve overall processes. When companies correct the underlying cause, they reduce the likelihood of the same problem happening again. Corrective and preventive action ensures that improvements made are sustainable and impactful in the long term.

Additionally, this focus on root causes allows companies to look at their processes more holistically. They can identify patterns or recurring issues that need systemic change. CAPA doesn’t just solve one problem at a time; it creates opportunities for widespread improvements. Businesses can continuously refine their operations, making them more efficient and resilient. When companies invest in finding and fixing root causes, they see long-term benefits in performance, customer satisfaction, and risk reduction.

CAPA Prevents Repeated Mistakes and Fosters Growth

CAPA’s preventive nature is what truly sets it apart as a driver of continuous improvement. Instead of merely reacting to problems after they occur, CAPA takes proactive steps to prevent them from happening again. By addressing potential risks before they materialize, companies avoid costly mistakes that can hinder progress. CAPA enables organizations to develop a forward-thinking approach, where the focus shifts from problem-solving to problem-prevention, which fosters a culture of growth and innovation.

This preventive mindset not only stops issues from recurring but also strengthens the entire organization. CAPA encourages teams to stay vigilant, continuously evaluating their processes and identifying areas of improvement. By implementing preventive measures, companies create an environment where learning from past experiences becomes part of the daily routine. This leads to better decision-making, as teams become more skilled at identifying warning signs and implementing corrective measures early.

Steps of an Effective Corrective and Preventive Action

Identify the Problem

Start by documenting the issue. Collect data and evidence to determine the scope of the problem.

Investigate Root Causes

Use root cause analysis tools like the “5 Whys” or fishbone diagram to uncover the underlying cause of the issue.

Develop a Corrective Action Plan

Based on your findings, create a plan to address the issue. Include specific actions, timelines, and responsible team members.

Implement Corrective Actions

Put your corrective actions into practice. Ensure that everyone involved understands their role in solving the problem.

Monitor and Validate

After implementing corrective actions, monitor the results. Ensure that the issue has been resolved and doesn’t recur.

Plan Preventive Actions

Analyze how you can prevent similar issues in the future. Develop preventive measures and incorporate them into your processes.

Continuous Monitoring

CAPA doesn’t end after implementation. Continuous monitoring is essential to ensure long-term success and foster ongoing improvement.

How Can CAPA Be Integrated into Daily Operations?

Encourage Employee Involvement to Drive Accountability

Employee involvement is key to integrating CAPA into daily operations. Employees often spot issues first because they work closely with the processes. By actively involving them in CAPA, you empower them to take responsibility for quality improvements. Encouraging employees to participate in reporting non-conformances helps identify problems quickly. This involvement creates a culture of accountability, where everyone feels responsible for improving processes. When employees know they play an active role in CAPA, they become more engaged in maintaining high-quality standards.

Moreover, encouraging employee participation in CAPA fosters continuous improvement. Employees bring valuable insights from their daily work, helping organizations identify root causes more effectively. Open communication is essential for this to happen. Employees should feel comfortable reporting issues without fear of blame or backlash.

Leverage Automation and Align CAPA with Business Goals

Using automation tools is a smart way to streamline Corrective and preventive action processes. Manually tracking corrective and preventive actions can be time-consuming and prone to errors. Automating workflows simplifies documentation, ensures timely updates, and provides real-time tracking of action items. Automation tools reduce the chance of missing important deadlines or steps in the process. By automating repetitive tasks, companies can focus more on solving the root causes and preventing future issues. This ensures that CAPA efforts remain efficient and effective over time.

Aligning CAPA with broader business goals helps integrate it into daily operations. Corrective and preventive action should not stand alone as a quality management tool; it should contribute to achieving key performance indicators (KPIs). When CAPA is linked to business objectives, it drives more focused improvements. For example, if a company aims to reduce product defects by a certain percentage, CAPA can help achieve that goal. Setting clear goals and tracking CAPA’s contributions toward them ensures continuous progress.

Corrective and Preventive Actions Ensure Regulatory Success

In highly regulated industries like pharmaceuticals and medical devices, Corrective and preventive action drives continuous improvement by ensuring regulatory success. Many regulatory bodies, such as the FDA and ISO, require organizations to have effective Corrective and Preventive Actionssystems. it creates a clear record of how companies identify and correct issues, which is crucial during regulatory audits. This documentation helps companies demonstrate their commitment to maintaining high standards and resolving problems effectively. When organizations provide detailed records, they build trust with regulators and avoid potential compliance issues.

Moreover, CAPA supports ongoing improvements that align with regulatory expectations. CAPA’s preventive approach focuses on solving problems before they escalate. By addressing the root causes and implementing preventive actions, companies avoid repeating mistakes. This helps businesses stay compliant and avoid penalties, which can be costly. CAPA ensures that organizations not only meet current regulations but also continuously improve their processes. By staying ahead of potential issues, businesses can maintain a strong regulatory standing while enhancing quality and performance.

How Does CAPA Foster a Culture of Continuous Improvement?

One of the most significant benefits of CAPA is that it fosters a culture of continuous improvement by encouraging proactive thinking. Instead of only reacting to problems, Corrective and Preventive Actions pushes teams to think ahead and prevent future issues. By focusing on preventive actions, Corrective and Preventive Actions turns problem-solving into an opportunity for growth. This approach helps companies avoid recurring problems and enhances overall efficiency. When employees consistently look for ways to improve processes, they contribute to long-term success. Proactive thinking becomes a valuable habit that leads to continuous development across the organization.

Additionally, CAPA promotes accountability by embedding it in the process. When teams document corrective and preventive actions, they take ownership of their roles. This sense of accountability ensures that everyone stays committed to maintaining high-quality standards. It also improves communication and transparency within the organization, as all team members know what actions are being taken and by whom. CAPA often involves multiple departments, improving cross-functional collaboration. Different teams work together to solve problems, leading to better communication and shared goals. This collaboration enhances decision-making and ultimately improves processes across the company.

What Are Common Challenges in CAPA Implementation?

While CAPA is a powerful tool, implementing it effectively can present several challenges. Below are common challenges and ways to overcome them:

Problems

Solutions

Lack of Resources

Ensure that you allocate adequate resources (time, personnel, tools) to address CAPA issues.

Poor Documentation

Document every step of the CAPA process to maintain transparency and accountability.

Resistance to Change

Provide training and involve employees in the CAPA process to build trust and reduce resistance.

Inconsistent Follow-Through

Set clear timelines and responsibilities for implementing and monitoring corrective and preventive actions.

Conclusion

In conclusion, Corrective and Preventive Actionsdrives powerful continuous improvement results by addressing both the root causes of existing issues and preventing future problems. Through improved quality control, increased efficiency, enhanced compliance, and stronger customer satisfaction, CAPA plays a vital role in helping organizations succeed. By integrating Corrective and Preventive Actionsinto daily operations, fostering a culture of continuous improvement, and measuring its effectiveness, businesses can ensure that they stay competitive and compliant in an ever-evolving landscape.

To unlock the full potential of CAPA, organizations should invest in proper training, allocate resources, and embrace digital tools to streamline the process. When CAPA becomes an integral part of the company culture, it drives powerful and lasting improvement.

References

Ershad Moradi

Ershad Moradi, a Content Marketing Specialist at Zamann Pharma Support, brings 6 years of experience in the pharmaceutical industry. Specializing in pharmaceutical and medical technologies, Ershad is currently focused on expanding his knowledge in marketing and improving communication in the field. Outside of work, Ershad enjoys reading and attending industry related networks to stay up-to-date on the latest advancements. With a passion for continuous learning and growth, Ershad is always looking for new opportunities to enhance his skills and contribute to pharmaceutical industry. Connect with Ershad on Facebook for more information.

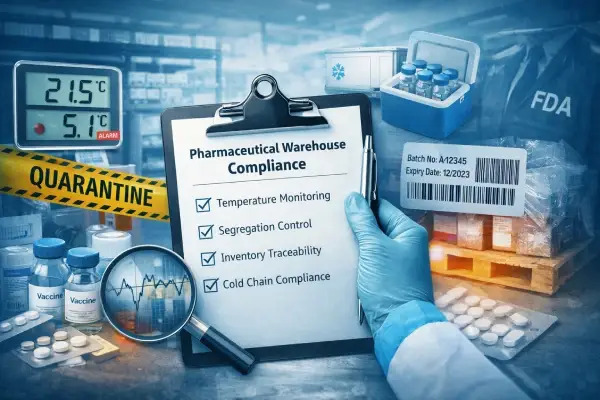

Pharmaceutical Warehouse in 2026: GMP Storage Requirements Guide

Effective drug storage compliance depends on validated storage conditions for pharmaceuticals, structured segregation control, and reliable batch traceability in warehouse operations. This guide explains how temperature excursion management and GDP compliance warehouse practices strengthen inspection readiness and regulatory defensibility.

GMP Interview in 2026: Questions and Answers with Audit Insight

More than 60% of regulatory observations in pharmaceutical manufacturing relate to documentation control, investigation quality, and procedural compliance gaps. GMP Interview preparation in regulated environments determines whether a candidate can operate safely under inspection pressure.

Harmonization in pharmacovigilance in 2026

Inspection trends show that inconsistent global safety practices remain a leading source of pharmacovigilance findings. This article explains how regulatory harmonization, aligned safety reporting, and coordinated oversight shape inspection outcomes and support compliant international pharmacovigilance operations.