If pharmaceutical cleaning validation feels like a regulatory minefield, you’re not alone. Many QA/QC professionals and validation engineers feel overwhelmed by the technical details, FDA expectations, and the pressure to “get it right the first time.”

The truth is: non-compliance isn’t just a risk—it’s a business threat. Improper equipment cleaning can lead to cross-contamination, product recalls, and failed audits. But with the right roadmap, you can move from confusion to clarity—fast.

This guide solves the common problems professionals face:

• Not knowing where to begin.

• Fear of audit failures.

• Confusion around protocols like swab sampling or TOC testing.

• Difficulty writing a cleaning validation SOP.

• Lack of access to practical tools and templates.

By following this actionable, easy-to-understand strategy, you’ll master pharmaceutical cleaning validation confidently—no guesswork required.

What Is Pharmaceutical Cleaning Validation?

Pharmaceutical cleaning validation ensures that your equipment is free from harmful residues before manufacturing the next product batch. It proves that your cleaning process consistently meets predefined safety standards. Whether you’re using Clean-in-Place (CIP) systems or manual cleaning, validation is essential.

Why does it matter? Because patients’ health is on the line. Contaminated equipment can result in cross-contamination, ineffective drugs, or toxic reactions.

Regulators like the FDA and EMA require a clear cleaning validation protocol that includes documented proof of consistent results.

For companies in the pharmaceutical and biotech sectors, failure to comply with cleaning validation regulatory requirements leads to costly recalls, warning letters, or worse—loss of manufacturing licenses.

✅ Master this foundational concept now with our in-depth Cleaning Validation Glossary

Sign up for Introduction to GMP Annex 1 Course

What Are the Main Objectives Behind Pharmaceutical Cleaning Validation?

Protect Patient Health

Protecting patient health is the top priority in pharmaceutical manufacturing. Every cleaning step must remove all traces of active ingredients and cleaning agents.

If residues remain, patients may suffer from unwanted side effects or harmful reactions. Therefore, companies must carefully plan and execute cleaning procedures. They must also verify that equipment is truly clean before reuse.

To achieve this, manufacturers follow strict cleaning validation acceptance criteria.

These criteria define safe residue levels that must not be exceeded. Teams use methods like swab sampling and rinse sampling to collect residue data. Then, they analyze results with tools such as TOC testing or HPLC cleaning.

If levels go beyond the limit, teams must repeat the cleaning and investigate the cause. This step-by-step approach helps prevent cross-contamination.

It also protects the quality of medicines and ensures patient safety. Above all, a solid cleaning validation protocol shows regulators that safety comes first.

Prevent Cross-Contamination

Cross-contamination can seriously harm patients and damage product quality. It happens when residue from one product transfers to another.

This risk increases in multiproduct facilities where equipment serves different drug types. Therefore, manufacturers must clean all surfaces thoroughly between batches. They must also confirm the cleaning process works every time.

To stop cross-contamination, companies follow strict cleaning validation steps.

First, they identify the worst-case product and equipment combination. Then, they choose strong cleaning agents and detailed procedures.

Next, they test surfaces using swab sampling or rinse sampling.

After that, they analyze the results with TOC or HPLC methods. If residue levels exceed the limits, they must repeat cleaning.

This process ensures no harmful substance moves to the next batch. It also protects patient safety and meets GMP requirements. Want to understand how regulations guide contamination control?

7 Key Elements of a Pharmaceutical Cleaning Validation Protocol

Objective and scope

Define what equipment and products are covered.

Roles and responsibilities

Assign tasks clearly to QA, QC, engineering, etc.

Worst-case selection criteria

Choose the hardest-to-clean product and equipment.

Cleaning procedure description

Include time, temperature, agents, and steps.

Sampling methods

Specify swab sampling, rinse sampling, or both.

Acceptance criteria

Set limits for residues (chemical, microbiological, detergent).

Analytical methods

Use validated techniques like TOC testing and HPLC cleaning.

How Do You Choose the Right Equipment Cleaning Procedure?

Define Worst-Case Scenarios

To start worst-case cleaning validation, teams must identify the hardest situations to clean. They should focus on surfaces that are rough, narrow, or have complex shapes.

These areas usually hold the most residue. At the same time, teams must look at the products used. Products with low solubility or high toxicity create more cleaning challenges.

Next, teams must run a cleaning validation risk assessment. They use this to choose the worst-case product and equipment pair. They should consider factors like product potency, batch size, and cleaning difficulty. Then, they assign scores using a clear matrix. After that, they explain each choice with documented reasons. This step helps justify the validation plan to regulators.

It also ensures the team focuses on the highest risk. As a result, the cleaning process becomes stronger and more effective. Always include this risk assessment in your cleaning validation protocol and master plan. It helps prove your process protects both products and patients.

Select Appropriate Cleaning Agents and Parameters

To select the right cleaning agents, you must first check product and equipment compatibility. Then, look at the residue profile of each product. Choose agents that dissolve or remove those specific residues.

Also, pick agents with the right cleaning mechanism—like surfactants or alkaline cleaners. This makes cleaning more effective and consistent.

Next, define the key cleaning parameters in detail. Always include time, temperature, and the number of rinses. Add mechanical actions like brushing or pressure spray if needed.

After that, document each step in your cleaning validation SOP. Also, add the details to your cleaning validation protocol. This ensures that every team member follows the same process.

More importantly, it allows you to repeat results with confidence. If changes occur, update the SOP and retest the procedure. This keeps your cleaning validation plan accurate and up to date.

As a result, you reduce risks and meet GMP expectations every time.

Top Tools for Automating Pharmaceutical Cleaning Validation

Digital Validation Management Systems

These tools store all protocols, acceptance criteria, and results in a validated platform. They support version control and audit trails—critical for maintaining data integrity in cleaning validation.

Portable TOC Analyzers and LIMS

Portable Total Organic Carbon (TOC) devices allow quick checks on-site. Laboratory Information Management Systems (LIMS) ensure traceability and compliance with cleaning validation guidelines FDA expects.

Cleaning Validation Software Platforms

These specialized systems integrate equipment cleaning logs, validation protocols, and analytical results in one dashboard. They also track cleaning validation lifecycle approach stages—from planning to revalidation.

Electronic Batch Records (EBR)

EBRs automate data capture and link cleaning activities directly to production records. This improves traceability and ensures cleaning validation documentation aligns with GMP and ALCOA++ principles.

Digital Swab Sampling Devices

These tools guide users step-by-step through cleaning validation swab method protocols. They reduce human error and automate sample ID tagging, location tracking, and time-stamping.

Why Does Documentation Matter in Pharmaceutical Cleaning Validation?

Every step of pharmaceutical cleaning validation must be backed by documentation. You must show a clear trail from planning to execution to acceptance.

Document the following:

- Cleaning validation protocol and SOPs

- Raw data and chromatograms from HPLC cleaning

- Swab and rinse sampling logs

- Deviations and CAPA reports

- Cleaning agent usage logs

- Cleaning validation lifecycle approach and revalidation triggers

Use controlled templates to ensure compliance and clarity.

Pharmuni tip: Validation success lives and dies by documentation. If it isn’t documented—it didn’t happen.

Conclusion

Pharmaceutical cleaning validation requires more than just clean surfaces. You need protocols, scientific proof, risk-based planning, digital tools, and strong documentation.

To recap:

- Learn the terminology (cleaning validation, CIP validation, worst-case selection, etc.)

- Follow SOPs with defined swab sampling and rinse sampling

- Validate using TOC testing and HPLC cleaning

- Apply lifecycle thinking with ALCOA++ principles

- Stay audit-ready with clear documentation and acceptance criteria

References

Ershad Moradi

Ershad Moradi, a Content Marketing Specialist at Zamann Pharma Support, brings 6 years of experience in the pharmaceutical industry. Specializing in pharmaceutical and medical technologies, Ershad is currently focused on expanding his knowledge in marketing and improving communication in the field. Outside of work, Ershad enjoys reading and attending industry related networks to stay up-to-date on the latest advancements. With a passion for continuous learning and growth, Ershad is always looking for new opportunities to enhance his skills and contribute to pharmaceutical industry. Connect with Ershad on Facebook for more information.

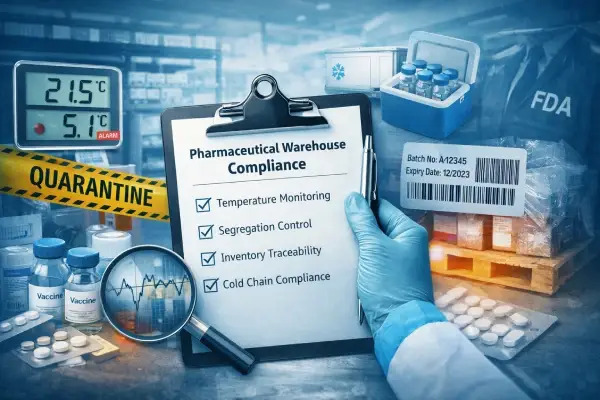

Pharmaceutical Warehouse in 2026: GMP Storage Requirements Guide

Effective drug storage compliance depends on validated storage conditions for pharmaceuticals, structured segregation control, and reliable batch traceability in warehouse operations. This guide explains how temperature excursion management and GDP compliance warehouse practices strengthen inspection readiness and regulatory defensibility.

GMP Interview in 2026: Questions and Answers with Audit Insight

More than 60% of regulatory observations in pharmaceutical manufacturing relate to documentation control, investigation quality, and procedural compliance gaps. GMP Interview preparation in regulated environments determines whether a candidate can operate safely under inspection pressure.

Harmonization in pharmacovigilance in 2026

Inspection trends show that inconsistent global safety practices remain a leading source of pharmacovigilance findings. This article explains how regulatory harmonization, aligned safety reporting, and coordinated oversight shape inspection outcomes and support compliant international pharmacovigilance operations.