In today’s competitive market, organizations must prioritize quality and continuous process improvement to stay ahead. By focusing on these principles, companies can enhance efficiency, reduce costs, and boost customer satisfaction.

This comprehensive guide explores how adopting a structured approach to quality and process improvement can transform your business. Whether you’re in manufacturing, healthcare, or service industries, understanding and implementing these strategies will help you achieve operational excellence and sustain growth.

What Is Quality and Continuous Process Improvement?

Quality and continuous process improvement refer to systematic efforts aimed at enhancing organizational processes, products, and services. It involves ongoing actions to identify inefficiencies, eliminate waste, and increase value for customers. These improvements lead to better compliance, higher productivity, and increased profitability.

Implementing these improvements requires a clear understanding of existing workflows and a commitment to incremental changes.

Organizations often use various methodologies, such as Six Sigma, Lean Manufacturing, and Kaizen, to guide their efforts.

The goal is to create a culture that constantly seeks better ways to operate, ensuring long-term success.

In essence, quality and continuous process improvement are about fostering an environment where every employee actively participates in refining processes — leading to sustainable development.

How Does Continuous Process Improvement Differ from Traditional Quality Control?

Continuous process improvement focuses on regularly making small changes to enhance overall performance. It involves everyone in the organization working together to find better ways to do tasks. In contrast, traditional quality control mainly checks products after production to find defects. It often relies on inspectors who catch mistakes before products reach customers. Continuous improvement aims to prevent problems before they happen, saving time and money.

Moreover, it encourages employees to suggest ideas for better processes. Traditional quality control sometimes leads to waste because problems are only fixed after they occur. Additionally, continuous improvement promotes a culture of ongoing learning and adaptation. It helps companies stay competitive by constantly evolving their methods. On the other hand, traditional quality control mainly maintains existing standards without much change.

Overall, continuous process improvement is proactive, while traditional quality control is reactive. This key difference helps organizations achieve higher quality and efficiency in their work.

Sign up for Laboratory Method Validation - Foundational Course

What Are the Main Objectives of Quality and Continuous Process Improvement?

Deliver products and services that meet or exceed customer expectations consistently.

Minimize defects, rework, and inefficiencies to save resources.

Streamline processes to maximize productivity and reduce cycle times.

Maintain adherence to industry standards and legal requirements.

Encourage employee engagement and continuous learning.

Why continuous process improvement is crucial

A Quality Management System (QMS) provides a structured framework to maintain and improve quality.

It standardizes processes, documents procedures, and fosters continuous improvement. For industries like pharmaceuticals and healthcare, compliance with standards such as ISO 9001 or GMP is essential.

Benefits of a robust QMS include:

- Enhanced product consistency

- Better regulatory compliance

- Improved risk management

- Increased customer trust

How can organizations effectively implement a QMS? Start by conducting gap analyses, training staff, and integrating continuous improvement practices.

Regular audits and management reviews keep the system effective

What Are the Top Tools for Process Improvement in Healthcare?

Root Cause Analysis

Identify underlying issues causing errors or delays.

Fishbone Diagrams

Visualize cause-and-effect relationships.

PDCA Cycle (Plan-Do-Check-Act)

Enable iterative improvements.

Value Stream Mapping

Map patient flow and identify bottlenecks.

Control Charts

Monitor process stability over time.

How to Implement Continuous Process Improvement in Your Organization?

Implementation begins with leadership commitment.

Leaders must champion a culture that values quality and innovation. Next, organizations should:

- Assess current processes: Map workflows and identify pain points.

- Set measurable goals: Define clear objectives aligned with business strategies.

- Train employees: Provide education on methodologies like Lean or Six Sigma.

- Encourage employee involvement: Promote suggestions and feedback.

- Utilize improvement tools: Apply relevant techniques such as process mapping or control charts.

- Monitor progress: Use KPIs to track improvements and adjust strategies accordingly.

Remember: Continuous process improvement is an ongoing journey, not a one-time project.

Regular reviews and adapting to new challenges sustain momentum.

What Are Proven Strategies for Effective Quality Management?

Successful organizations adopt these strategies:

- Leadership commitment: Set the tone from the top.

- Customer focus: Prioritize customer needs and feedback.

- Data-driven decision-making: Use metrics to guide improvements.

- Employee empowerment: Involve staff at all levels.

- Standardization: Document procedures to ensure consistency.

- Continuous training: Keep teams updated on best practices.

- Regular audits: Identify gaps and opportunities for improvement.

How do these strategies improve quality? They create a proactive environment where quality is embedded in everyday activities, leading to sustained excellence.

Conclusion

Achieving excellence through quality and continuous process improvement requires a strategic approach, dedicated effort, and a culture that values ongoing learning. By understanding the core principles, adopting proven methodologies like Lean and Six Sigma, and leveraging effective tools, your organization can unlock new levels of efficiency and customer satisfaction.

Remember, continuous improvement is not a one-time project but an ongoing journey. Start today by assessing your current processes, engaging your team, and implementing actionable strategies. For professionals seeking to deepen their expertise, Pharmuni’s Laboratory Method Validation – Foundational Course offers invaluable knowledge to enhance your career and contribute to your organization’s success.

Take action now! Visit Pharmuni to explore training options and certifications that can elevate your process improvement capabilities. Embrace the power of quality and continuous process improvement to propel your business toward sustainable excellence.

References

Ershad Moradi

Ershad Moradi, a Content Marketing Specialist at Zamann Pharma Support, brings 6 years of experience in the pharmaceutical industry. Specializing in pharmaceutical and medical technologies, Ershad is currently focused on expanding his knowledge in marketing and improving communication in the field. Outside of work, Ershad enjoys reading and attending industry related networks to stay up-to-date on the latest advancements. With a passion for continuous learning and growth, Ershad is always looking for new opportunities to enhance his skills and contribute to pharmaceutical industry. Connect with Ershad on Facebook for more information.

Pharmaceutical Job Search – How To Find Top Biotech Careers

Kick-start your pharmaceutical job search with a clear plan. Learn where to find quality biopharma job listings, how to filter roles fast, and when to apply. Then upskill with micro-courses, add ISO-9001 certificates, and practice interviews.

Explore Top Remote Pharma Jobs and Start Working Online

Remote work is reshaping pharma hiring. Learn which fields thrive online, from medical writing to pharmacovigilance. See why flexibility, global access, and cost savings matter. Then, search Pharmuni Jobs and type “Remote” in the location filter to discover verified roles and apply fast.

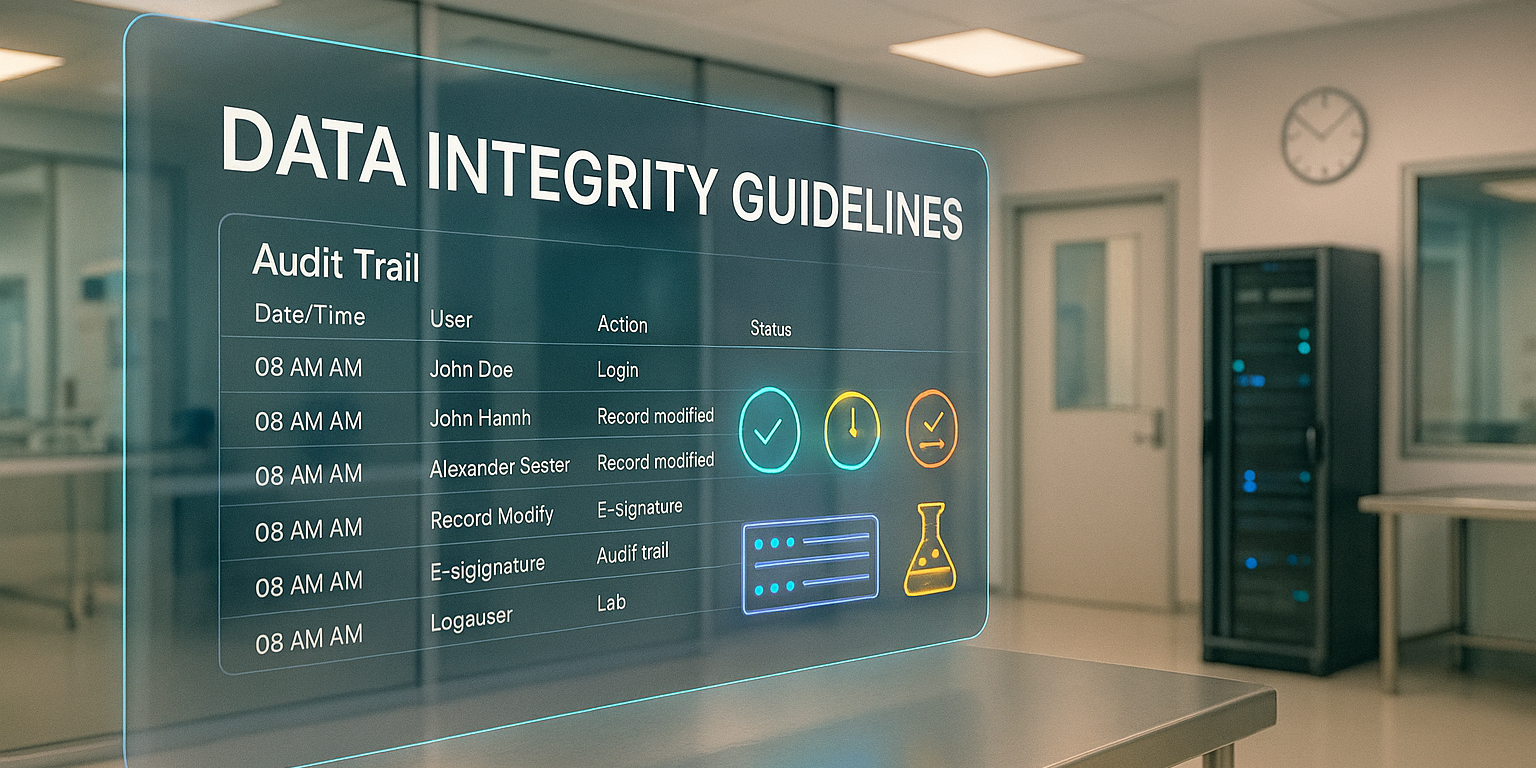

Data Integrity Guidelines: What You Must Do Now

Build trust with data integrity guidelines that translate ALCOA+ into daily controls. Secure systems, validate suppliers, enable audit trails, and prepare for Annex 11 updates. Boost compliance, speed releases, and protect patients. Start now—read the full guide and download the one-page checklist today.