You sit down, the panel nods, and then the real test starts: a live task. Not trivia. Not buzzwords. Real-world GMP interview tasks mirror the shop floor, the batch room, and the quality office. These tasks reveal how you think, how you write, and how you defend decisions under time pressure. Therefore, you need a plan that works on paper and in practice. Moreover, you must show disciplined problem-solving, crisp documentation, and risk-based judgment.

This guide breaks down the most common GMP interview tasks and shows how to ace each one. I bring a decade in SEO-driven pharma writing and immersion in quality systems. Consequently, you get practical steps, clear frameworks, and ready-to-use phrases. You will learn how to structure your answers, reduce errors, and communicate like a trusted QA professional. Additionally, you will see how to connect your actions to regulations and data integrity. Use the checklists. Practice the templates. Finally, walk into the interview with confidence and leave with an offer.

GMP Interview Tasks: What Hiring Managers Really Test

Hiring managers rarely want perfect memory. Instead, they want consistent judgment. GMP interview tasks therefore focus on your method, not just your final answer. Typically, you will review a redacted batch record, analyze a deviation, or prioritize CAPA actions. You may also respond to an auditor’s finding. Every prompt checks the same core: Can you identify risk, explain rationale, and document actions so anyone can reproduce them? Furthermore, can you do it fast and clean?

Two signals matter most. First, structure shows maturity. Use a repeatable pattern like “Context → Risk → Options → Decision → Evidence → Next steps.” Second, traceability shows credibility. Tie every observation to a source: SOP number, CFR citation, Annex clause, or a validated data point. Moreover, label assumptions, define acceptance criteria, and close the loop with verification steps. Because GMP interview tasks simulate your daily job, they reward clarity, not flair.

GMP Interview Tasks: The 10 You’ll See Most

- Demonstrate a batch record review: Flag deviations, missing signatures, out-of-sequence steps, and illegible data.

- Showcase a deviation of triage: Categorize the impact on safety, identity, strength, quality, and purity.

- Map root cause: Use 5 Whys and confirm with evidence, not opinion.

- Explain a CAPA plan: Define containment, corrective, preventive, owner, due date, and effectiveness of checks.

- Draft a change of control: Describe scope, validation impact, documents to update, and risk rating.

- Calculate a cleaning validation swab limit: Present assumptions, math, and acceptance criteria.

- Outline an OOS investigation: Separate lab errors from manufacturing root causes and define retest rules.

- Review data integrity compliance: Apply ALCOA+ and identify risky manual steps.

- Prioritize a risk register: Use severity, occurrence, and detectability to focus on effort.

- Role-play an audit response: Address the finding, cite the standard, and commit to verifiable actions.

Mastering GMP Interview Tasks: Deeper Scenarios You Must Nail

A panel may push beyond basics. Consequently, they hand you a short dossier and a timer. You must read, infer, decide, and defend. Keep nerves steady by using a universal structure: restate the problem, list constraints, identify risks, propose options, select one with justification, then define measurement and verification. Additionally, write in audit-ready sentences and reference documents precisely.

Concise writing wins time. Therefore, open with a one-sentence decision, then support it with bullets or short paragraphs. Use transitions to guide reviewers across your logic. Moreover, assign owners and deadlines, because accountability is part of the assessment. Always define how you will prove effectiveness, or the task remains open.

CAPA Investigation Task

You receive a deviation summary: a tablet press jam causes weight variability. First, restate the issue and its impact on dosage uniformity. Next, triage the patient risk and product disposition. Then, run 5 Whys on probable causes: feeder rate, tooling wear, lubrication, operator training, or humidity control. Moreover, gather evidence: maintenance logs, environmental records, calibration certificates, and operator statements.

Select a root cause only when evidence converges. Consequently, define corrective actions that remove the cause and preventive actions that stop recurrence. Update SOPs, training matrices, and PM schedules as needed. Additionally, set effectiveness checks: trending weight RSD post-maintenance, first-hour verification runs, and targeted internal audits. Close with a clear acceptance criterion and a 30-day follow-up.

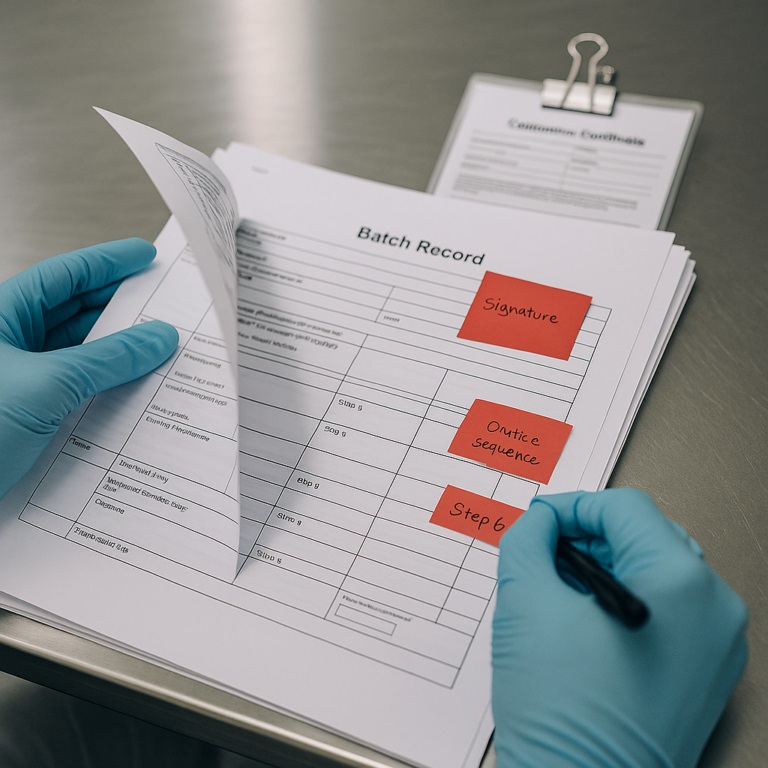

Batch Record Review Task

You get five pages with subtle defects. Start with completeness: signatures, dates, a lot of identifiers, and step sequences. Then test data integrity: legibility, raw data traceability, and corrected entries with justification. Moreover, verify calculations and cross-references to equipment logs. Identify any unplanned deviations and ensure attachments exist, such as calibration certificates.

Document findings in a tidy table: “Observation → Risk → Reference → Required Action → Owner → Due Date.” Therefore, the panel sees rigor and calm control. Close by recommending product status—release, hold, or reject—based on evidence and SOP thresholds. Additionally, propose systemic fixes if you find patterns, such as recurring transcription errors.

Tools and Frameworks to Ace Interview Tasks

- ALCOA+ for data integrity. Anchor every entry to Attributable, Legible, Contemporaneous, Original, Accurate, plus Complete, Consistent, Enduring, and Available. Also, describe how your plan enforces each attribute.

- 5 Whys and Ishikawa. Drive beyond symptoms with layered cause mapping. Consequently, align evidence to the most probable root.

- Risk Priority Number (RPN). Score severity, occurrence, and detectability to prioritize CAPA resources. Additionally, justify your thresholds.

- SMART actions. Make tasks Specific, Measurable, Achievable, Relevant, and Time-bound. Moreover, pair each with an effectiveness metric.

- GxP citations. Reference 21 CFR 211, EU GMP Vol. 4, Annex 1, and site SOPs. Therefore, every decision feels grounded.

- Verification and validation. Separate installation/operational checks from performance proof. Also, define requalification triggers.

- Sampling plans. Select statistically defensible sizes and acceptance criteria. Consequently, avoid underpowered conclusions.

- Human factors lens. Consider ergonomics, training quality, and workload effects. Additionally, propose practical mitigations.

- Change impact analysis. Evaluate effect on validation of state, cleaning, labels, and electronic systems. Moreover, update controlled docs.

- Audit-ready writing. Use short sentences, numbered steps, and cross-references. Therefore, reviewers follow your logic fast.

Preparation vs Practice: Turning Knowledge into Interview Performance

Interviews rarely measure memory; they measure execution under pressure. Therefore, preparation must build a structure, while practice must test that structure. You need tight methods for GMP interview tasks, not vague slogans. Start with a repeatable blueprint you can deploy in minutes. Then drill it until muscle memory is over. Moreover, treat every simulation like the real floor: timeboxed, evidence-based, and audit-ready. Clear writing and decisive choices will carry you.

Next, align your tools to the job. You will cite Annex 1 and 21 CFR 211 precisely. You will rank risks with RPN and enforce ALCOA+ in every record. Additionally, you will close the loop with effective checks. Finally, you will communicate status in one sentence, then defend with data. Preparation builds the kit; practice proves the operator. Together, they turn pressure into a performance advantage.

Build a GMP Portfolio

A compact, de-identified portfolio signals judgment before questions begin. Recruiters see how you think, write, and verify. Therefore, curate documents showcasing traceability, risk logic, and clean formatting. Keep scope lean but meaningful. Moreover, label each item with context, decision, references, and effectiveness. Pair each artifact with a one-minute oral summary delivered calmly.

- Evidence pack: sample batch review with observation table, risk ranking, and release recommendation.

- Investigation trail: deviation narrative using 5 Whys, supporting logs, and confirmed root cause.

- Action plan: CAPA with containment, corrective, preventive, owners, dates, and verification.

- Validation slice: change impact analysis showing validation state, updated SOPs, and training matrix.

- Data integrity map: ALCOA+ checklist tied to actual entries and audit trail excerpts.

Arrange the artifacts in audit flow. First, present the decision. Then reveal supporting data. Additionally, cross-reference each observation to an SOP or clause. Use short sentences, numbered steps, and tables. Avoid jargon unless you define it. Finally, rehearse the deck with a colleague who challenges weak links. Capture their questions and add clarifying notes. Refinement keeps the kit sharp, current, and relevant for future interviews.

Practice Under Realistic Constraints

Practice under the same constraints you will face. Set timers, remove internet crutches, and work from fixed packets. Therefore, your brain learns to prioritize evidence and decisions. Simulate interruptions to harden focus. Moreover, write by hand to catch legibility issues before interview day.

- Timed sprints: 20–30 minute drills for batch reviews, deviations, and audit responses.

- Paper first: annotate the packet, circle risks, and tag clauses before drafting.

- Decision upfront: write the conclusion line first, then assemble supporting evidence.

- Citation habit: note CFR or Annex references as you read, not afterward.

- Defense rehearsal: record a five-minute verbal walkthrough and remove hedging language.

After each sprint, debrief with a scorecard: clarity, traceability, citations, effectiveness. Assign one improvement to carry into the next drill. Additionally, build a template bank: observation tables, CAPA headers, risk matrices. Keep them on a page you can recreate from memory. Finally, rotate scenarios across dosage forms, equipment, and environments. Breadth reduces surprises and exposes gaps. Confidence comes from evidence: you solved similar patterns, over time. Walk in prepared, speak clearly, and close answers with owners, dates, and verification.

Common Red Flags and Fixes

Vague root causes

Statements like “operator error” without evidence show weak analysis. Instead, tie behavior to training gaps or unclear SOPs.

Missing effective checks

Plans without verification look unfinished. Define metrics, timeframes, and acceptance criteria.

No risk ranking

Equal weight on all findings wastes resources. Prioritize using an RPN or equivalent scheme.

Sloppy documentation

Illegible notes and undefined acronyms break traceability. Standardize your template and glossary.

Regulatory name-dropping

Citing “the regs” without specific clauses weakens credibility. Reference clauses precisely.

Over-engineering fixes

Expensive controls for minor risks signal poor judgment. Match control strength to risk.

Data integrity blind spots

Unexplained overwrites or backdated entries are fatal. Escalate and document remediation.

Emotional defensiveness

Pushback without evidence erodes trust. Acknowledge gaps and commit to data-based updates..

Unassigned actions

CAPA items without owner’s stall. Assign names, roles, and due dates.

No systemic view

Single-batch fixes ignore patterns. Trend deviations to find recurring causes.

Communication Strategies That Stand Out

Great analysis fails if people cannot follow it. Therefore, shape messages for speed and clarity. Start with the decision, then walk reviewers through evidence, risk, and controls. Moreover, state assumptions and acceptance criteria in plain language. Use short, active sentences and numbered steps. Additionally, mirror audit language to reduce debate. When challenged, keep tone calm, evidence-first, and solution-oriented.

- Lead with a one-sentence conclusion that declares status and action. Then unpack why.

- Anchor every claim to data, lot numbers, and clause references that others can verify.

- Expose assumptions explicitly, and define limits, samples, and acceptance criteria up front.

- Quantify risk using severity, occurrence, detectability; justify priorities with thresholds and trends.

- Cite ALCOA+ controls for each record step; describe how the process enforces them.

- Close with owners, dates, and effectiveness checks; specify what success looks like.

Consequently, reviewers can trace logic without hunting. However, they will press on weak links. Anticipate two likely objections for every recommendation. Prepare source numbers and alternative paths in advance. Furthermore, avoid jargon unless you define it. Replace vague phrases with measurable outcomes. Finally, end every answer with a clear disposition: release, hold with condition, or rejection with rationale. This rhythm earns trust during GMP interview tasks and converts pressure into credibility. Also, pause after key points when challenged.

The 10 Task Playbooks

- Batch record review: “Status: Hold due to missing second-person verification on step 7; require documented re-review.”

- Deviation triage: “Impact potential on potency; immediate containment executed; initiate investigation per SOP-DEV-012 within 24 hours.”

- Root cause analysis: “Most probable cause worn tooling confirmed by maintenance logs; replace and add PM frequency.”

- CAPA plan: “Corrective: recalibrate line; preventive: revised SOP and training; effectiveness: trend RSD ≤ 2% over 3 lots.”

- Change control: “Scope: feeder upgrade; validation impact: OQ/PQ partial; update SOP-OPR-005 and labels.”

- Cleaning validation math: “Carryover limit = (MDD × Potency × Safety factor)/Surface area; swab acceptance ≤ calculated limit.”

- OOS investigation: “No analyst error evident; expand to manufacturing causes; retest only under SOP-LAB-021 rules.”

- Data integrity: “All entries contemporaneous and legible; electronic audit trail reviewed; no unexplained overwrites.”

- Risk register: “Top risk RPN 196; implement interlock and add daily verification; reassess in two weeks.”

- Audit response: “Agree with finding per 211.68(b); action plan submitted with owners, dates, and verification steps.”

Your 24-Hour Prep Plan for GMP Interview Tasks

Deadlines loom, so you need a crisp, realistic plan. This 24-hour schedule turns theory into execution for GMP interview tasks. Start by simulating pressure, not comfort. Therefore, timebox every drill and remove internet crutches. Work from fixed packets and annotate like you would on the plant floor. Moreover, lead with decisions, then prove them with traceable evidence. Keep notes legible, numbered, and cross-referenced. Additionally, capture clause citations while reading, not afterward. Consequently, you reduce backtracking and protect accuracy. Finally, close each drill with owners, dates, and effectiveness checks to show end-to-end thinking.

- Morning sprint: Run a 30-minute batch-record review. Write the decision first. Tag risks, clauses, and acceptance criteria.

- Mid-morning review: Score clarity, traceability, and citations. Rewrite one weak paragraph. Convert observations into an action table.

- Lunch drill: Recreate your standard templates from memory. Include CAPA headers, RPN matrix, and data-integrity checklist.

- Afternoon defense: Record a five-minute verbal walkthrough. Remove hedging. Add precise CFR 211 or Annex 1 references.

- Evening refresh: Skim ALCOA+, sampling basics, and OOS rules. Build a one-page “methods” card for pocket recall.

- Night routine: Pack portfolio artifacts, pens, and calculator. Set alarms. Visualize the opening one-sentence conclusion.

Confidence comes from repetition under constraints. Therefore, cycle the same packets once more at double speed to stress-test recall. Adjust your templates based on snags you encountered. Moreover, replace vague language with measurable thresholds and verification steps. Sleep on a wind, not more reading. Consequently, you arrive clear-headed, structured, and ready to execute GMP interview tasks with calm precision.

Do you want expert feedback from pharma experts?

Conclusion

Hands-on simulations can feel intimidating. However, GMP interview tasks give you control. You choose the structure. You decide the evidence. You have clarity. Therefore, lean on repeatable methods: ALCOA+, 5 Whys, RPN, SMART actions, and audit-ready writing. Additionally, present decisions first and connect them to standards with exact citations. Reviewers notice rigor and calm execution.

Build a lean portfolio and practice under a timer. Then defend your choices with data, not volume. Because manufacturing, quality, and compliance depend on reliable judgment, your interview should demonstrate exactly that. Moreover, close every task with owners, due dates, and effectiveness checks. That final step separates good from great.

Ready to find pharma roles that fit your strengths?

References:

[1] 21 CFR Part 211 — Current Good Manufacturing Practice for Finished Pharmaceuticals (eCFR)

[2] EudraLex Volume 4 — EU Guidelines for Good Manufacturing Practice (European Commission)

[3] ICH Q9(R1) — Quality Risk Management (Official ICH Step 4 PDF)

[4] MHRA — Guidance on GxP Data Integrity (policy page with latest update details)

Stephanie Männicke

Digital Marketing Especialist at Zamann Pharma Support, brings 8 years of experience in Corporate and Digital Communication. Specializing in Digital Marketing and Content Creation, Stephanie is currently focused on creating strategic content for Pharmuni's networks, especially content on topics such as recruitment, onboarding and employer branding. Outside of work, Stephanie is a mum, a crocheter and a movie fan. An avid reader and in search of expanding her knowledge, Stephanie is always looking for ways to innovate communication in the digital environment and connect people in a genuine way.

Master GxP Validation in 2026: Meaning, Key Steps, and Validated State Control

Auditors want evidence you can trace, not opinions you can explain. GxP validation links intended use, requirements, risk, and test results into one story. When

Master GMP Compliance in 2026: Meaning, Core Elements, and How to Implement

GMP compliance keeps medicines safe, consistent, and traceable across every batch. This guide explains core GMP elements, practical rollout steps, and common pitfalls. It also

History of Pharmacovigilance: From the Thalidomide Crisis (1961–2026) to GMP Oversight

Thalidomide in 1961 changed drug safety forever. Since then, pharmacovigilance has grown from crisis response to proactive risk management. Today, teams track signals, tighten reporting

FAQs:

GMP interview tasks simulate real shop-floor decisions. You review records, analyze deviations, and propose CAPA. Therefore, hiring managers to see your judgment, traceability, and speed.

Build a lean portfolio with a mock batch review, one deviation, and a CAPA plan. Then run timed drills. Moreover, rehearse a five-minute verbal defense for each artifact.

Reference 21 CFR Part 211, EU GMP Volume 4, and Annex 1. Additionally, link each claim to site SOPs. Precise clauses strengthen credibility.

Use: Context → Risk → Options → Decision → Evidence → Next steps. Consequently, reviewers can follow your logic without hunting.

Separate containment, corrective, and preventive actions. Assign owners and dates. Furthermore, define effectiveness of checks and acceptance criteria.